Infrared Roof Scans

Find trapped moisture in flat roofs before it becomes a costly repair. Our drone-based thermal scanning reveals what's hidden beneath the membrane.

Request a Quote →See What Visual Inspections Miss

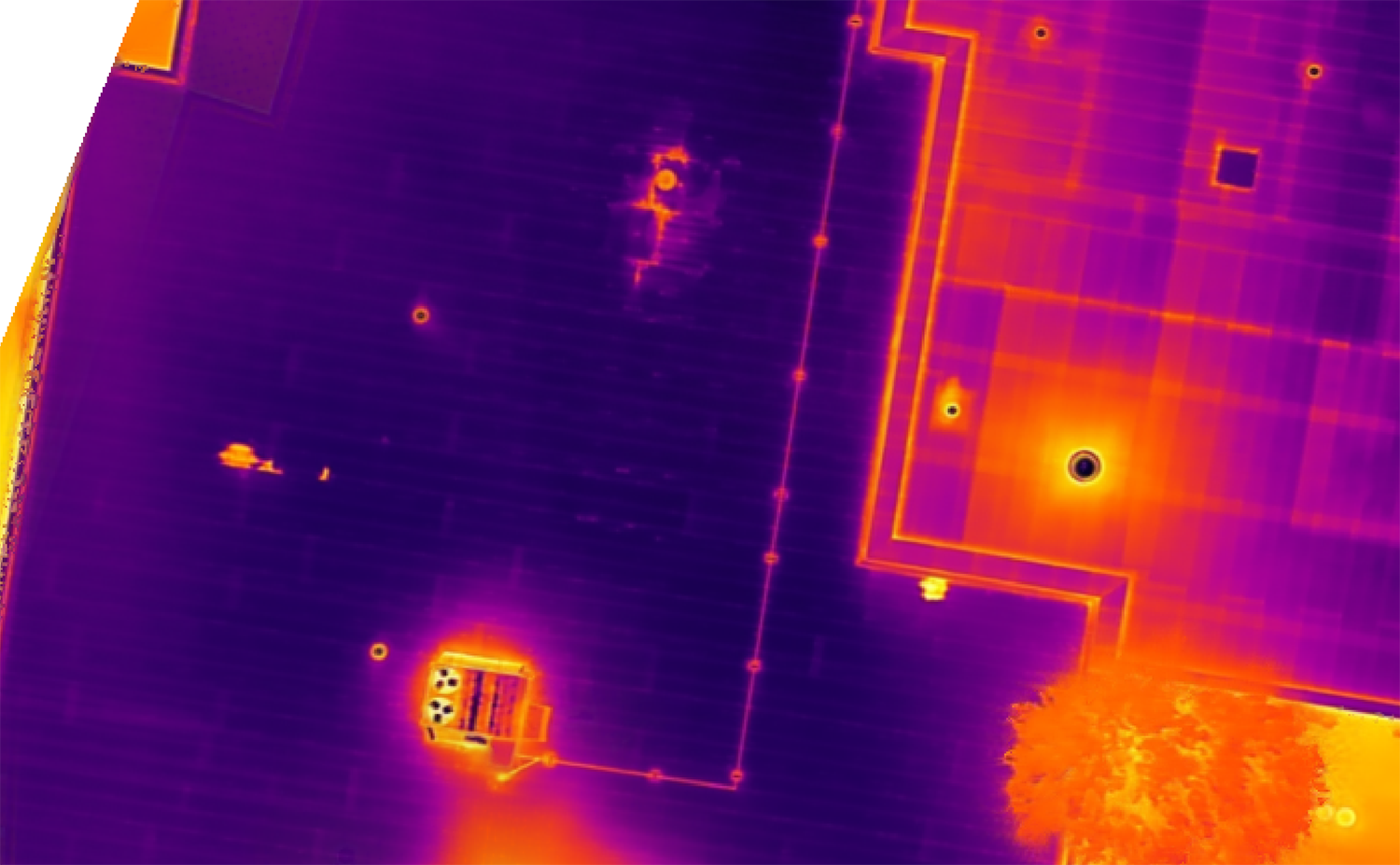

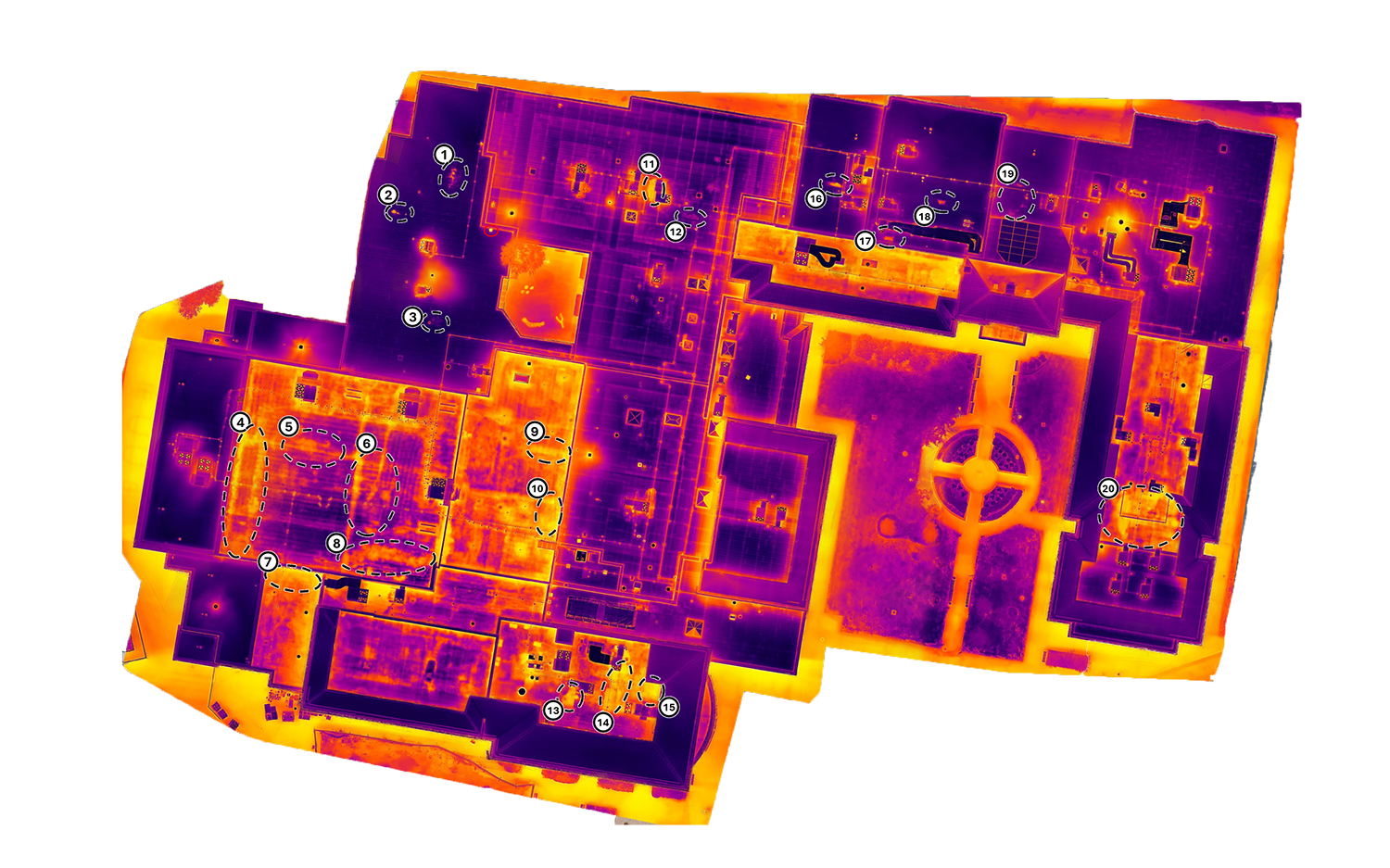

Wet insulation holds heat longer than dry material. After sunset, as your roof cools, our thermal cameras detect these temperature differences and map them with centimeter-level accuracy.

Unlike ground-based thermal scans or handheld walkovers, our drone captures the entire roof from directly overhead. This perpendicular angle produces cleaner, more reliable data that we process into georeferenced thermal maps and AutoCAD drawings.

Level II sUAS Certified Thermographer

Level II sUAS Certified Thermographer

Hidden Problems, Revealed

Trapped Moisture

Water beneath the membrane from leaks or failed seams

Wet Insulation

Saturated insulation that's lost its thermal value

Thermal Anomalies

Unusual heat patterns indicating potential problems

Insulation Gaps

Missing or displaced insulation causing heat loss

Why Aerial Thermal Scanning

Better Accuracy

Capturing thermal data straight down (nadir) produces more accurate readings than angled ground-based scans. We map the entire roof systematically, not just sample areas.

No Roof Access Required

Nobody walks the roof during our scan. Less liability, no disruption to building operations, and no risk of damaging the membrane.

Faster Coverage

We scan commercial roofs of any size in a single evening. For large facilities, we deploy multiple teams to capture everything before conditions change.

Lower Cost

No scaffolding, no boom lifts, no extensive roof access setup. Drone-based scanning is more efficient, and those savings get passed to you.

What to Expect

Planning

We monitor weather and schedule the scan for optimal conditions. Backup dates are always planned.

RGB Survey

Daytime flight captures high-resolution imagery showing surface conditions, debris, and ponding.

Thermal Survey

After sunset, we capture thousands of infrared images as the roof releases stored heat.

Analysis & Delivery

We process both datasets, measure anomalies in AutoCAD, and deliver your complete report.

Deliverables

RGB Roof Map

High-resolution orthomosaic showing visible conditions, ponding, debris, and surface defects.

Thermal Roof Map

Georeferenced infrared map highlighting temperature variations and thermal anomalies.

CAD Measurements

Anomalies traced and measured in AutoCAD with square footage for repair planning.

Clients We Work With

Thermal Roof Inspections Across Southern Ontario

For large industrial or commercial facilities, we travel throughout Ontario.

Common Questions

What roof types work best for thermal scanning?

Flat and low-slope commercial roofs with membrane systems (TPO, EPDM, modified bitumen, built-up) work best. Steep-slope residential roofs with shingles or tiles typically aren't suitable due to material properties.

What weather do you need?

We need dry conditions with no rain for at least 24 to 48 hours prior. Clear skies, low wind, and a temperature differential of at least 20°F between the roof and exterior. We always schedule a backup date in case conditions change.

How long does it take?

On-site work typically runs 4 to 6 hours total: a daytime RGB flight (30 to 60 minutes) and an evening thermal scan (1 to 3 hours depending on size). Processing and report delivery takes 5 to 7 business days.

What is ASTM C1153?

ASTM C1153 is the industry standard for locating wet insulation using infrared imaging. It specifies scanning conditions, methodology, and documentation requirements. Our surveys follow ASTM C1153 protocols, producing results that roofing consultants and insurance companies recognize. Learn how we apply this standard →

Can infrared find all leaks?

Infrared detects moisture that has accumulated in insulation over time. It won't catch brand-new leaks that haven't spread yet, and it can't see through ponding water or metal decking. That's why we always pair thermal with RGB imagery and recommend verification core samples for critical decisions.

What does it cost?

Pricing depends on roof size, complexity, and deliverables. Contact us with your roof size and location for a custom quote. Many clients find that targeted repairs based on thermal data cost far less than replacing an entire roof.

Find Hidden Moisture Before It's Costly

Schedule a thermal roof scan and get the data you need to make informed repair decisions.

Request a Quote →CONTACT

Request a Quote

Fill out the form below and we'll get back to you within one business day.