Drone Inspections

Safe, efficient, and detailed inspections for roofs, buildings, solar arrays, and infrastructure. No scaffolding, no ladders, less liability.

Request a Quote →Inspections Without the Risk

Traditional inspections put people on roofs, scaffolding, and boom lifts. Drone inspections significantly reduce that risk while capturing more detailed data. Our high-resolution RGB and thermal cameras document conditions from every angle, producing actionable reports in days instead of weeks.

Whether you need a one-time assessment or ongoing monitoring, we tailor each inspection to your requirements. From flat roof moisture scans to high-rise facade surveys, our certified pilots and thermographers deliver results you can trust.

Inspection Types

Drone Roof Inspection

High-resolution visual inspections for flat, sloped, commercial, and industrial roofs. Identify damage, debris, and wear without walking the roof.

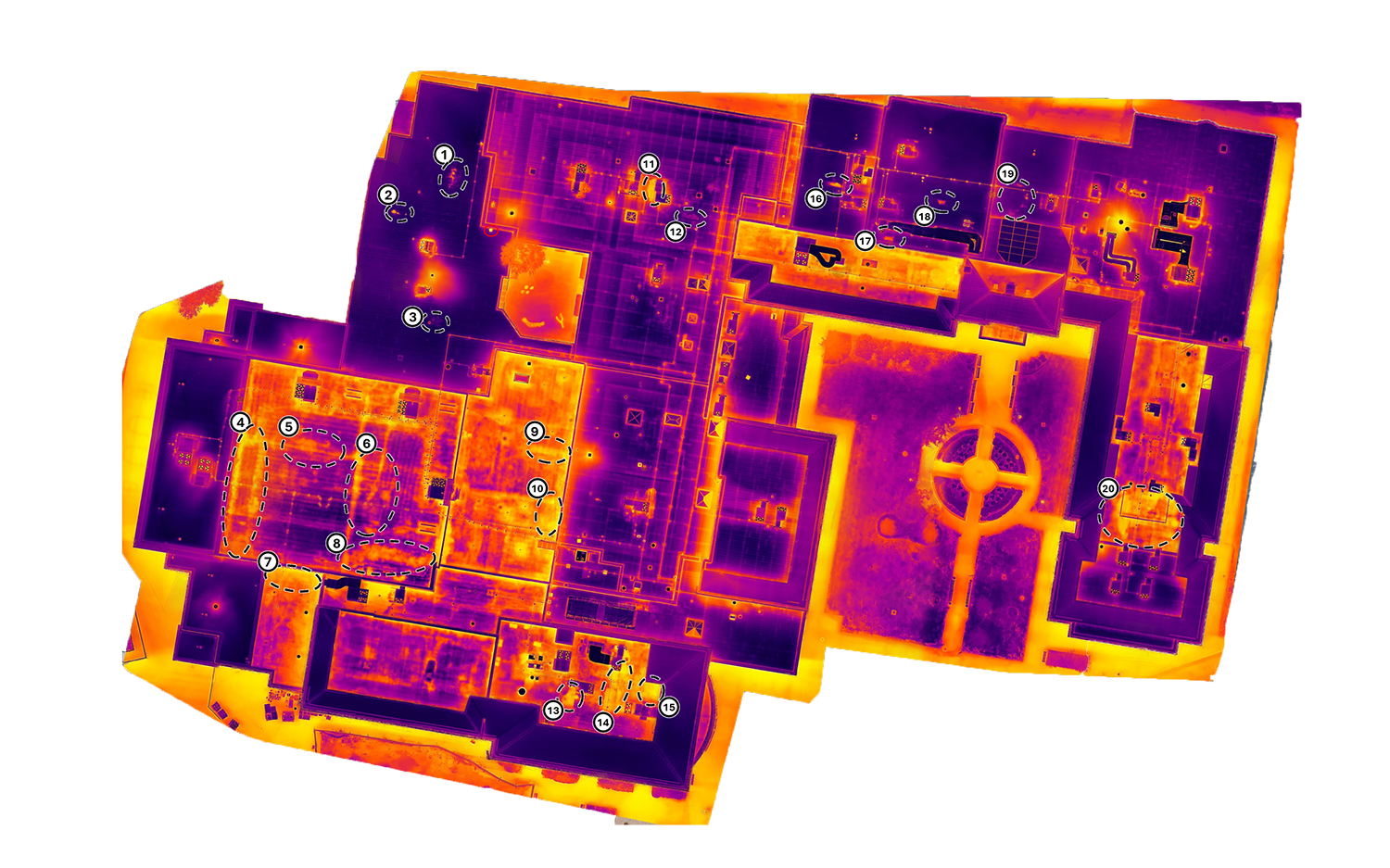

Infrared Roof Inspection

Thermal scanning detects trapped moisture and wet insulation in flat roofs. ASTM C1153 compliant with Level II certified thermographers.

Solar Panel Inspection

IEC 62446-3 compliant thermal inspections for PV arrays. Detect hot spots, cell damage, and underperforming modules across your system.

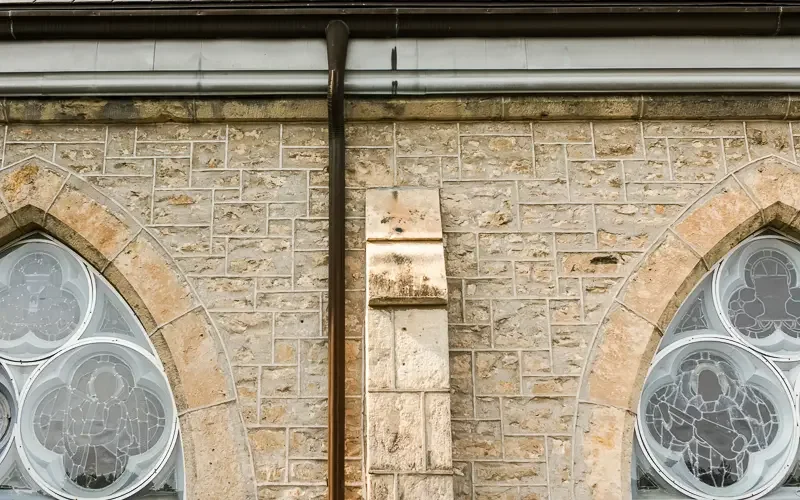

Facade Inspection

Detailed exterior assessments for high-rise buildings. Document cracks, spalling, failed sealants, and cladding issues without scaffolding.

Why Choose Aerial Inspections

Safer

No personnel on roofs, scaffolding, or boom lifts. Significantly reduce liability and fall risk.

Faster

Most inspections complete in hours, not days. Deliverables typically ready within 2-5 business days.

Cost-Effective

No scaffolding rental, no equipment setup. More efficient operations mean lower costs for you.

Assets and Infrastructure

Common Questions

What assets can you inspect with drones?

Buildings and facades, roofs (flat and sloped), bridges, solar farms, cell towers, industrial plants, parking structures, and other infrastructure. If it's hard to access or risky to inspect manually, drones are likely a good fit.

How long does delivery take?

Most single-site inspections are delivered in 2-5 business days. We typically provide an executive summary first, followed by full annotated image sets and reports.

Do you carry insurance and comply with regulations?

Yes. We carry commercial aviation liability insurance, maintain documented safety management systems, and comply with all Transport Canada regulations. We coordinate with NAV CANADA when applicable and integrate with on-site safety protocols.

Can I watch the inspection live?

Yes. We can set up a live video feed so you or your team can observe the drone inspection in real time.

Are drone inspections as accurate as manual inspections?

Often more accurate. Drones capture high-resolution imagery and precise measurements using photogrammetry and professional equipment. This level of detail frequently exceeds what's possible with traditional manual inspections.

What do I receive after the inspection?

Depending on the service, you'll receive high-resolution imagery, thermal maps, annotated reports, measurements, and all the details contractors, consultants, or insurance adjusters need to take action.

Ready for a Safer Inspection?

Tell us about your project and we'll recommend the right inspection approach for your needs.

Request a Quote →CONTACT

Request a Quote

Fill out the form below and we'll get back to you within one business day.