Solar Panel Inspections

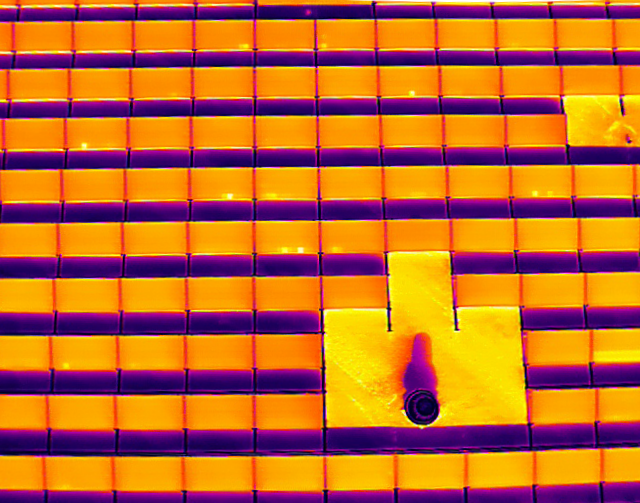

Find underperforming modules before they cost you. Drone-based thermal scanning identifies hot spots, cell damage, and system faults across your entire array.

Request a Quote →Protect Your Solar Investment

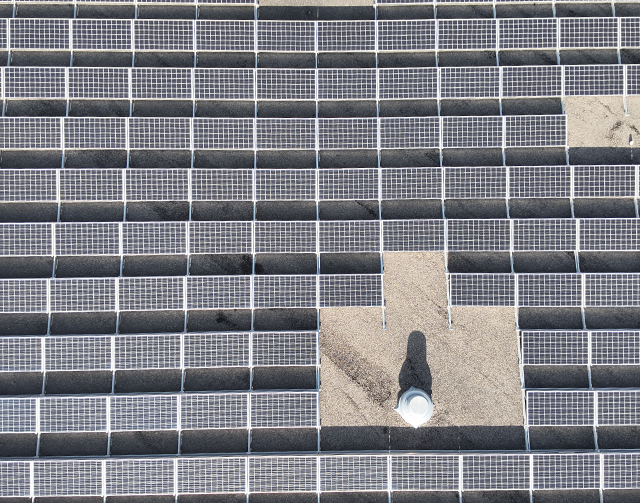

PV modules are expected to perform for 20+ years, but defects from manufacturing, transport, installation, or field conditions can silently erode output. Our drone-mounted RGB and thermal cameras scan your entire array, identifying issues that ground-based inspections miss.

We deliver georeferenced thermal maps and orthomosaics that pinpoint problem modules. Import our data into your preferred PV analysis software or use our annotated reports to prioritize maintenance.

Detectable Faults

Hot Spots

Cell Damage

Cracked Glass

String Outages

Junction Box Failures

Diode Defects

PID Effects

Combiner Box Heat

What to Expect

Consultation

We review your array layout and confirm the level of detail needed (module, diode, or cell level).

Site Survey

On-site assessment of irradiance conditions, shading, and any access considerations.

Drone Capture

RGB and thermal flights under IEC-compliant conditions (600+ W/m², low wind, full string activation).

Delivery

Georeferenced orthomosaics, raw imagery, and reports ready for your PV analysis software.

Deliverables

RGB Orthomosaic

High-resolution visual map of your entire array showing physical condition, soiling, and shading.

Thermal Orthomosaic

Georeferenced thermal map with temperature data for every module. Import into your PV software.

Raw Imagery

All RGB and radiometric JPEG (RJPG) files for import into third-party analysis platforms.

Clients We Work With

Common Questions

What faults can thermal inspection detect?

Thermal imaging reveals hot spots, cell damage, cracked glass, PID, string outages, junction box failures, diode defects, loose connectors, and thermal patterns from soiling or shading. Balance-of-system issues like combiner box overheating can also be flagged.

What is IEC TS 62446-3?

It's the international standard for outdoor infrared thermography of PV systems. Compliance means flight conditions, sensor settings, reporting, and defect classifications meet utility-grade requirements. Results are repeatable, traceable, and accepted for warranty, insurance, and O&M documentation.

What conditions do you need?

Per IEC standards, we need stable irradiance (typically 600+ W/m²), low wind, dry modules, and full string activation. We schedule flights around weather windows to ensure accurate thermal contrast.

How often should we inspect?

Most owners conduct one full thermal scan per year, plus targeted inspections after storms, equipment changes, or performance drops. For large portfolios, bi-annual scans help quantify degradation and prioritize maintenance.

How long does it take?

Commercial rooftops and small ground-mounts typically scan in under a day. Utility-scale sites may take 1 to 2 days. Data delivery is usually 1 to 3 business days after capture.

Can findings support warranty or insurance claims?

Yes. Because we inspect under IEC conditions and deliver traceable geolocation and delta-T values, results can be used for warranty claims, insurance investigations, O&M validation, or pre-acquisition due diligence.

Maximize Your Solar Output

Schedule a thermal inspection and identify underperforming modules before they impact your bottom line.

Request a Quote →CONTACT

Request a Quote

Fill out the form below and we'll get back to you within one business day.